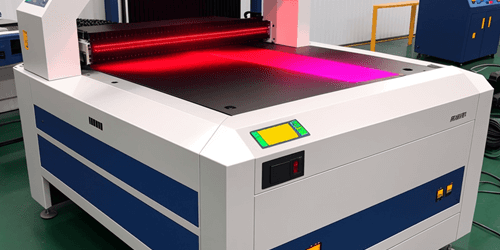

With the advancements in technology, the traditional engraving process has evolved significantly. One such example is the electronic engraving machine, a digital device used for engraving different surfaces, including paper, metal, glass, and wood. For printers, the transition to these digital engraving machines brings a wide array of benefits that dramatically improve the printing process.

Here are the top five reasons electronic engraving machines are an ideal choice for printers.

Precision and Consistency

These machines operate digitally, using software to guide the engraving process, ensuring that every cut is accurate to the smallest detail. Furthermore, unlike manual methods where human errors can occur, electronic engraving machines deliver consistent results every single time, ensuring the quality of prints and the satisfaction of customers.

Speed and Efficiency

The second reason pertains to speed and efficiency. Electronic engraving machines have automated processes that are much faster than traditional manual methods. This speed doesn’t just result in faster production times but also enables printers to meet large orders efficiently. The ability to produce large volumes of high-quality engravings quickly is a significant advantage in the competitive printing market.

Versatility

Electronic engraving machines are highly versatile, capable of engraving a vast array of materials, from paper and wood to metal and glass. This versatility allows printers to offer a wider range of products and services to their clients, thus expanding their business opportunities. Furthermore, the digital nature of these machines allows printers to easily switch between different engraving designs, making it possible to customize orders to meet the specific needs of each client.

Reduced Operational Costs

While the upfront cost of these machines might be higher than traditional methods, the long-term savings are substantial. The reduced need for manual labor, the decrease in material waste due to precision engraving, and the lower maintenance costs associated with these machines can lead to significant cost savings over time.

Ease of Use and Safety

Finally, electronic engraving machines are generally easier to use and safer than manual engraving methods. Once the design is programmed into the machine, the engraving process can be executed with a simple push of a button. This ease of use reduces the learning curve for new operators and increases productivity.

This website has some of the most advanced electronic engraving machines in the market today.